|

Xi'an Silk Genesis Textile Co., Ltd

|

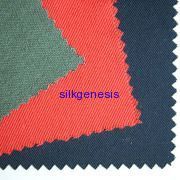

dyed nomex fabric plain

| Price: | 12.0~18.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Nomex fabric, High-temperature endurable, flame retardant

we could product the fabric as your sample.

accept small order, please contact with us

Nomex Fireproof fabric

1.100% aramid,aramid&cotton,aramid&viscose,aramid&wool

2.High-performance Flame Retardant

3.OEM,ODM

Aramid

Aramid usuallly has 2 model: Meta Aramid and Para Aramid.

Meta Aramid possess excellent heat stability, flame retardance, electric insulation, chemical stability, radiation resistance.

Para Aramid possess extremely high strength.

Meta Aramid Fiber

Color: Natural white

Solution dyed/Dope dyed

Meta aramid fiber can works normally at 206 C for long term. No ignition, no melting or dripping.

Application: Filtration fabric; sewing thread, felts, knitted fabrics. The solution dyed/dope dyed fiber usually be used in applications requiring superior colour fastness.

About Aramid Fabrics

| 1 | What is Aramid fiber Fabric ? |

Aramid fiber is a strong, heat-resistant fiber formed of polymers with repeating aromatic groups branching from a carbon backbone. In the polyamide fibers, at least 85% of the amide linkages are attached directly to two aromatic rings. Two types of Aramid materials are used in. Meta Aramid paper which is used for making honeycomb core materials required for sandwich construction Para- Aramid fibers are made by the solution polycondensation of diamines and diacid halides. The oriented Para substituted aromatic units provide a rod like polymer. The rod like structure results in a high glass transition temperature and poor solubility. They are not spinnable by conventional process and hence they are made by the dry- jet wet spinning of liquid crystalline polymer solutions. | |

| 2 | Why Aramid Fabric is used ? |

| High tensile strength, good impact strength, low density lighter than glass, excellent toughness, high abrasion resistance, excellent resistance to fatigue, good wear resistance, negative axial coefficient of thermal expansion. | |

| 3 | Where Aramid Fabric is used ? |

They are used in aerospace and military applications, for ballistic rated body armor Fabric and ballistic composites, High performance, low weight, flexible armour e.g. Body armour Flak jackets. Anti-ballistic composites e.g. mobile screens Helmets Spall linings Primary armour Insert plates Bomb blankets Vehicle armour. | |

| 4 | When Aramid Fabric is used? |

| Aramid fibers are known for their large hardness and resistance to penetration. Because of their toughness Aramid fibers are used where high impenetrability is required, e.g. bulletproof vests, bike tyres, airplanes wings, and sport equipment. . Aramid is characterized by its excellent resistance to heat, as it neither melts nor ignites in normal levels of oxygen. Aramid is used extensively in the production of protective apparel, air filtration, thermal and electrical insulation. |

| 5 | How Aramid Fiber is produced? |

| Aramid are manmade organic fibers produced from aromatic polyamides. Polymerization of monomers TDC, PPD along with NMP, CaCl2 solvents results in PPTA.AT this stage chemical and heat resistance properties are obtained but is in powder form. During coagulation extraction with H20 solvent is recovered .Next stage involves dissolving polymer in sulphuric acid at low temp.-10oC.Self oriented liquid crystal molecules are obtained by extrusion which imparts good mechanical properties. Aramid fiber variants are standard modulus, high modulus and high tenacity fibers. Modulus can be increased during heat treatment under tension at 4500C. | |

| 6 | What are advantages of using aramid fiber reinforcements? |

| Aramid fibers show excellent tensile, impact and toughness properties. Also they have no thermal expansion along with vibration absorption and damping properties. | |

| 7 | What are constrains of aramid fiber reinforcements? |

| Aramid fiber shows poor compression strength. They are UV sensitive and have 4% moisture absorption. They are costly compared with other regular reinforcements and machinability is poor. |